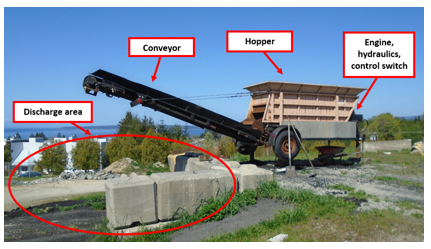

Asphalt Conveyor Unit #826

Summary:

The asphalt conveyor #826 is used to load stockpiled asphalt into the hot box on #824 for re-heating.

- Read and understand operation manual and safe work procedure for #824.

- Stand clear of loader/backhoe when hopper is being filled with asphalt.

- Keep clear of conveyor and auger chain when unit is running.

- Keep out from under conveyor discharge.

- Shut down the engine before clearing out underneath the unit.

- Use appropriate PPE.

Hazards:

- Noise

- Entanglement

- Overhead hazard – falling debris

- Mobile equipment

- Working at height

- Eye injury

- Muscle strain

Personal Protective Equipment (PPE) Required:

Hard hat

- CSA approved safety footwear

- Work gloves

- Hearing protection

- High visibility apparel

- Eye protection

Pre Set-Up:

- Pre-trip the unit – engine oil, fuel, hydraulic fluid, grease points, condition of conveyor belt, conveyor support cables.

- Ensure that hopper is empty.

- Back unit #824 underneath the conveyor outlet.

- Turn on and warm up engine.

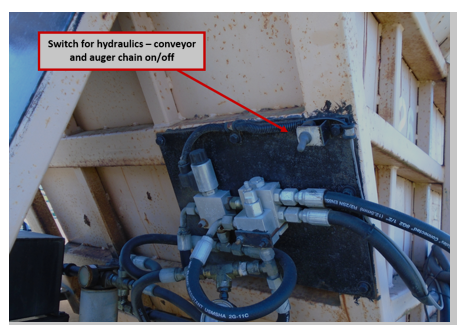

- Once engine has warmed, increase rpm and engage the auger chain/conveyor switch. Check for proper function.

- Disengage auger chain/conveyor, shut down engine until ready to begin the loading process.

Task procedure:

- Use a loader or backhoe to carry asphalt from the stockpile to unit #826.

- Asphalt must be broken up – avoid loading pieces larger than 6” in diameter.

- Fire up engine on #826, increase rpm about halfway, and engage the auger chain/conveyor switch. Conveyor belt should be running smoothly – if not, increase engine speed slightly.

- If using a ground assistant, ensure that they stay clear of the loader/backhoe at all times.

- Gently fill the hopper with asphalt.

- Asphalt will carry up the conveyor and drop into the hot box on #824. Monitor the level and placement of the asphalt. Stay out from under the discharge area.

- Breeze may blow grit from the falling asphalt; wear eye protection..

- Shut down the conveyor and adjust position of #824 if needed during loading.

- Fill the hot box as per operation manual for #824.

- When hot box has been filled, shut down conveyor and turn off engine.

- Using the ladder, reach with a hoe or rake and ensure that the side vents and door hinges on #824 are clear of asphalt.

Post Procedure:

- Pull #824 out from under the conveyor.

- If there is still asphalt in the hopper or on the conveyor, place loader/backhoe bucket under the conveyor discharge. Operate the conveyor until it is clear of material; turn off conveyor and shut down engine.

- Shovel spilled asphalt out from under the auger and conveyor into loader/backhoe bucket. Ensure that the area around the unit stays clear of debris.

- Deposit excess asphalt back in the stockpile.